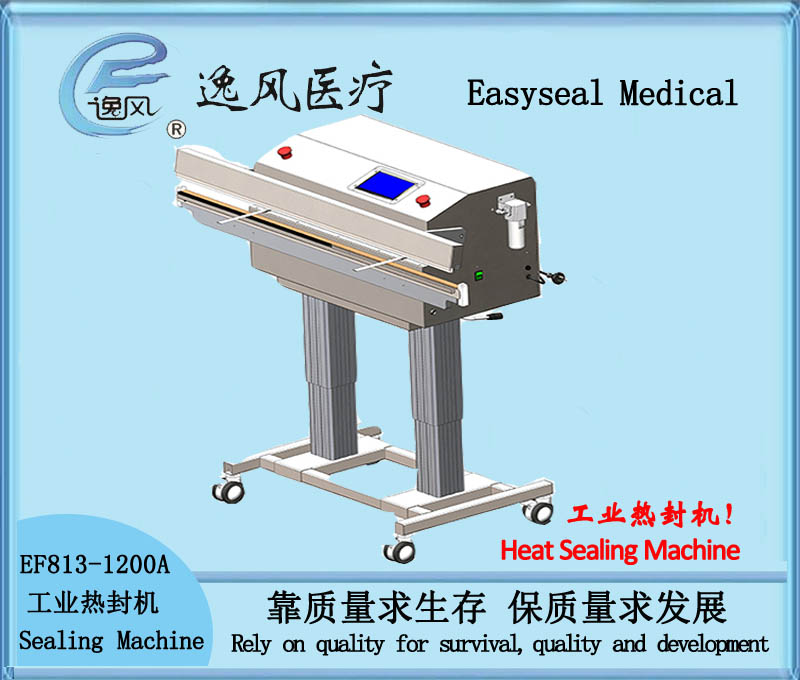

Heat sealing width: 3/5/8mm can be customized

Heat sealing length: 500/800/1200mm

Working temperature: 100~200℃ adjustable

Sealing height: customizable lifting table

Temperature control accuracy: ≤ 1%

Compressed air pressure: 0.5~0.8 Mpa

Negative pressure source: built-in negative pressure pump

Operating noise: ≤ 75 dB

AC power supply: 220V±10% 50Hz

Work rate: 800 W

Maximum current: 16 A

Insurance wire: 10A×2

鲁公网安备 37039002000410号

鲁公网安备 37039002000410号